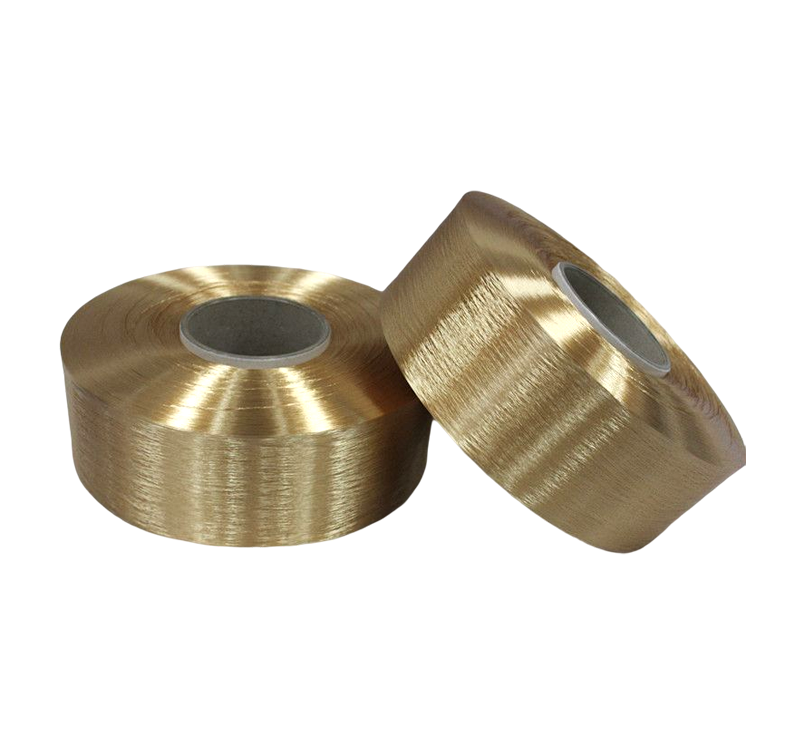

The environmental impact of manufacturing polyester full stretch yarn is a critical concern as the textile industry grapples with sustainability challenges. Polyester full stretch yarn, known for its excellent elasticity, durability, and vibrant color retention, is produced using bright polyester chips and color masterbatch through advanced spinning technologies. While these properties make it a preferred choice for a variety of applications—from home textiles to activewear—its production and disposal pose significant environmental issues.

The primary environmental concern with polyester full stretch yarn lies in its reliance on petrochemical resources. The production of polyester involves the extraction of fossil fuels, which contributes to greenhouse gas emissions and climate change. Additionally, the manufacturing process is energy-intensive, further exacerbating its carbon footprint. The dyeing and finishing processes add another layer of environmental impact, as they often involve the use of hazardous chemicals and large quantities of water. Wastewater from these processes can pollute local water sources if not properly treated.

Another major environmental issue is related to the disposal of polyester products. Unlike natural fibers, polyester is not biodegradable and can persist in the environment for hundreds of years. This leads to the accumulation of microplastics in oceans and soil, which poses a threat to marine and terrestrial life. Furthermore, the shedding of microplastics during washing adds to the pollution problem, affecting water quality and wildlife.

In response to these environmental concerns, there are several sustainable alternatives and practices emerging in the textile industry. One approach is the development of recycled polyester, which uses post-consumer plastic bottles or pre-consumer waste to create new yarns. This method reduces the demand for virgin polyester and helps divert plastic waste from landfills and oceans. Recycled polyester also generally requires less energy and water during production compared to virgin polyester.

Another promising development is the use of bio-based or biodegradable fibers. Innovations in textile technology are leading to the creation of polyester alternatives derived from renewable resources, such as plant-based materials. These fibers aim to offer similar performance characteristics as traditional polyester while reducing reliance on fossil fuels and improving end-of-life disposal options. Companies are also investing in closed-loop production systems that recycle water and chemicals, minimizing environmental impact throughout the manufacturing process.

Moreover, advancements in dyeing technologies, such as waterless dyeing techniques and the use of natural dyes, are helping to reduce the ecological footprint of textile production. These methods not only cut down on water usage and chemical discharge but also improve the overall sustainability of polyester full stretch yarn.

Overall, while Polyester full stretch yarn presents certain environmental challenges, the industry is making strides toward more sustainable practices. The shift towards recycled materials, bio-based alternatives, and innovative production techniques reflects a growing awareness and commitment to reducing the environmental impact of textile manufacturing. As these technologies continue to evolve, they offer hope for a more sustainable future for polyester and other synthetic fibers in the textile market.

English

English 中文简体

中文简体

Home

Home