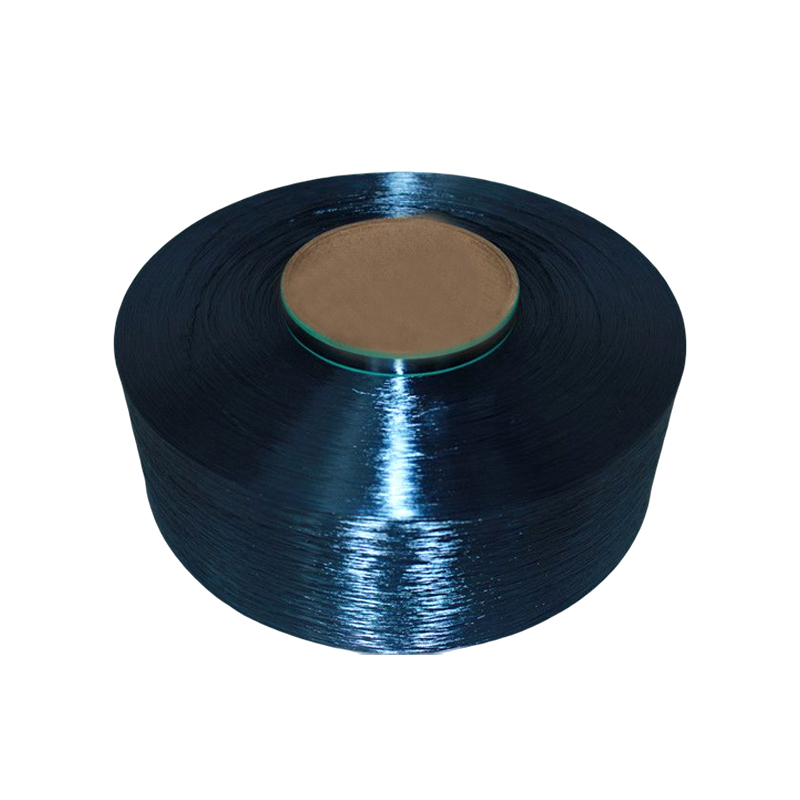

When it comes to storing and handling Polyester Full Stretch Yarn (FDY), ensuring its longevity and performance is key to maintaining the quality of your products. Whether you're using FDY for home textile fabrics, round knitting machines, warp knitting, webbing, or luggage, proper storage is crucial to prevent damage or deterioration that could impact the yarn's appearance, strength, and functionality. So, how can you ensure that your FDY stays in pristine condition from the moment it's received until it's used in production? Let’s dive into the best practices that will help you preserve the superior quality and vibrant color of this versatile yarn.

First and foremost, the storage environment plays a significant role in maintaining the integrity of FDY. Since polyester yarns, particularly FDY made from bright polyester chips and color masterbatch, can be susceptible to temperature and humidity fluctuations, it’s essential to store them in a cool, dry place. Extreme temperatures and excessive humidity can cause the yarn to degrade, leading to issues like reduced elasticity, fading, or even breakage during production. A climate-controlled room is ideal, with temperatures between 15°C and 25°C (59°F and 77°F), and humidity levels maintained at around 50%. If possible, avoid storing FDY in direct sunlight or near heat sources, as UV rays can deteriorate the color and weaken the fibers.

When it comes to the physical handling of FDY, gentle care is essential to avoid unnecessary stress on the yarn. Ensure that the rolls of yarn are stored on shelves or in storage units where they won’t be crushed or compressed. Proper stacking is key—avoid placing heavy items on top of the rolls, as this can cause them to deform or develop tension that affects their performance. It’s also a good idea to keep the yarn rolls in their original packaging to protect them from dust, dirt, and accidental damage. For added protection, consider wrapping the rolls with a breathable material, such as a fabric cover, to shield them from any environmental factors that may lead to deterioration.

Another important factor to consider is how the yarn is handled during transport and movement within the facility. Whether you’re moving FDY to different parts of the warehouse or preparing it for shipment, always handle the yarn with care to prevent tangling, stretching, or snags. Avoid dragging the rolls across rough surfaces, and if you need to move multiple rolls at once, use carts or equipment designed for safe transport. If you’re working with customized FDY, which may be of varying thicknesses and properties, be extra cautious when managing these specialized materials to prevent any unnecessary strain that could lead to damage.

Lastly, regular inspections and maintenance are crucial to identify any issues early on and prevent them from becoming larger problems. Periodically check the stored yarn for signs of damage, discoloration, or any change in texture that could indicate improper storage conditions. A quick visual check can help catch any small problems before they affect the entire batch. Additionally, if your FDY is being used in a high-demand environment like knitting or weaving, consider conducting a test run with a small batch of yarn before starting full production to ensure its quality has been maintained throughout its storage.

The key to preserving the excellent performance and appearance of Polyester Full Stretch Yarn lies in maintaining the right environmental conditions, handling the yarn with care, and performing regular inspections. By following these best practices, you can ensure that the FDY stays in top shape, ready for use in high-quality home textiles, fashion garments, or any other application you require.

English

English 中文简体

中文简体

Home

Home