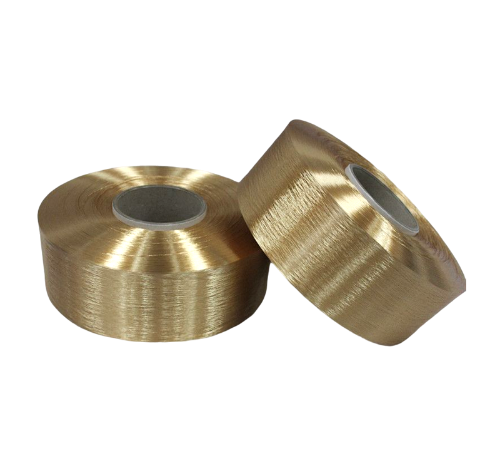

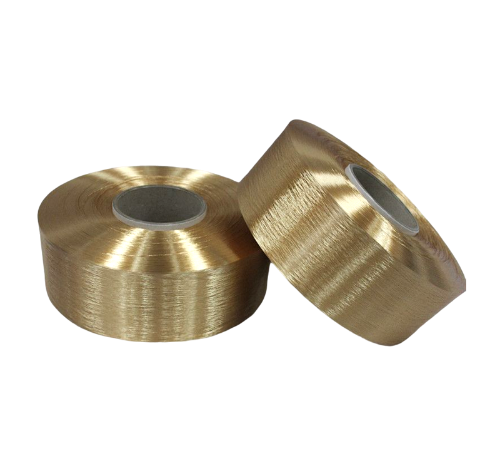

Polyester full stretch yarn is a type of synthetic yarn made from polyester fibers that are stretched and twisted to create a yarn that has a high level of elasticity. The chemical composition of polyester full stretch yarn typically includes the following components:

Polyester polymer: The primary component of polyester full stretch yarn is a synthetic polymer made from repeating units of ethylene terephthalate. This polymer is known for its strength, durability, and resistance to stretching, making it an ideal material for creating stretchy yarns.

Plasticizers: To increase the flexibility and elasticity of the polyester fibers, plasticizers such as diethylhexyl phthalate (DEHP) may be added to the yarn. These additives help to lower the glass transition temperature of the polymer, allowing the fibers to stretch and recover more easily.

Lubricants: Lubricants such as silicone oil may be added to the yarn to reduce friction between the fibers during the manufacturing process and to improve the feel and appearance of the finished yarn.

Pigments: Polyester full stretch yarn may be dyed with pigments to create a range of colors and patterns.

Antioxidants: To prevent the degradation of the polyester fibers during storage or use, antioxidants such as butylated hydroxytoluene (BHT) may be added to the yarn.

It's important to note that the exact chemical composition of polyester full stretch yarn may vary depending on the manufacturer and specific product.Meanwhile,The production process of polyester full stretch yarn typically involves the following steps:

Polymerization: The first step is to produce the polyester polymer by polymerizing ethylene terephthalate monomers. The monomers are heated and mixed with a catalyst to initiate the polymerization reaction, which results in the formation of long chains of polyester molecules.

Extrusion: The polyester polymer is then extruded through a spinneret, which is a small, nozzle-like device that has many small holes. As the polymer emerges from the spinneret, it is cooled and solidified, forming thin, continuous filaments.

Drawing: The solidified filaments are then heated and stretched in a process called drawing. This process aligns the polymer chains and increases the strength and durability of the fibers. The degree of stretching can be controlled to create different levels of elasticity in the yarn.

Texturizing: After the drawing process, the polyester fibers are texturized to give them a more natural feel and appearance. This is achieved by passing the fibers through a series of heated rollers or jets of air that twist and crimp the fibers.

Dyeing: The polyester fibers are then dyed using a variety of methods, such as solution dyeing or skein dyeing. This allows the fibers to be colored in a range of colors and patterns.

Winding: The dyed and textured polyester fibers are wound onto bobbins or cones, ready to be used in textile production.

The exact production process may vary depending on the manufacturer and specific product, but these are the general steps involved in producing polyester full stretch yarn.

English

English 中文简体

中文简体

Home

Home