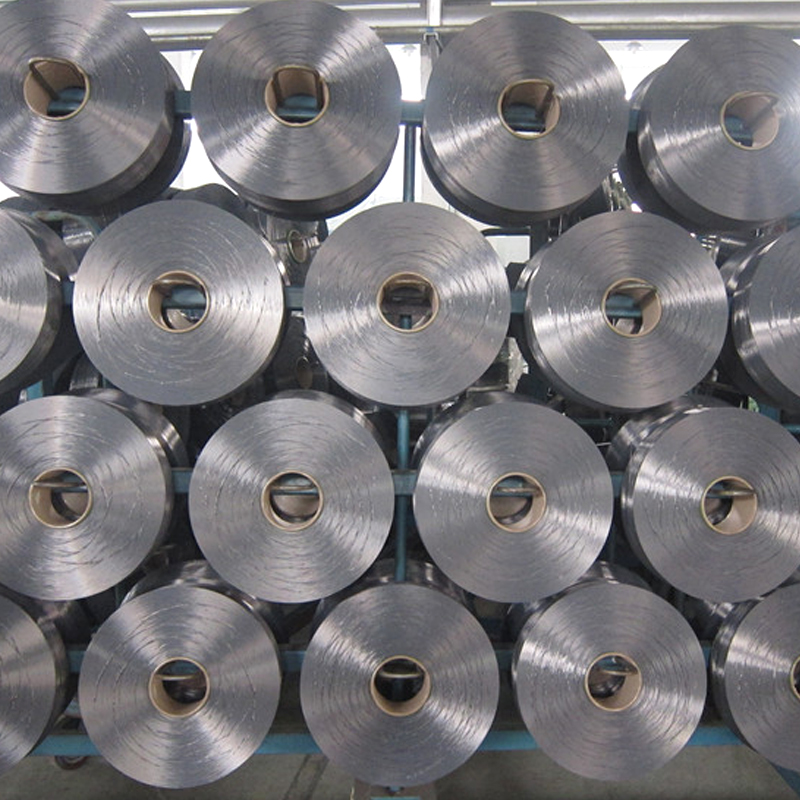

Polyester colored POY (Partially Oriented Yarn) has emerged as a game-changer, offering unmatched versatility for applications ranging from everyday apparel to heavy-duty industrial textiles. Unlike traditional dyeing methods, this pre-colored yarn integrates pigment directly into the polymer matrix during high-temperature melt spinning, ensuring vibrant hues and exceptional colorfastness. But what truly sets polyester colored POY apart is its ability to adapt to demanding processing conditions while maintaining structural integrity—a critical factor for modern textile engineers.

High-Speed Textile Machinery: Pushing the Limits of Processing

Polyester colored POY excels in high-speed manufacturing environments, where precision and efficiency are non-negotiable. During processes like draw-texturing or air-jet texturing, the yarn’s uniform molecular orientation and stable viscosity ensure smooth handling, even at rapid production speeds. This minimizes downtime caused by breakage or uneven tension, a common challenge with conventional fibers. For instance, in air-jet texturing—a method that creates bulkier, softer yarns for upholstery and activewear—the POY’s pre-colored formulation eliminates the risk of surface abrasion during mechanical manipulation, preserving color vibrancy. Engineers often highlight how the yarn’s thermal stability prevents melting or deformation under the intense heat of high-speed rollers, ensuring consistent output for applications like automotive textiles or technical sportswear.

Technical Textiles: Balancing Functionality and Aesthetics

When it comes to technical textiles, performance cannot come at the cost of visual appeal. Polyester colored POY strikes this balance by embedding color resilience into its core. Consider flame-retardant fabrics used in protective gear: while additives like phosphorus compounds enhance safety, they can compromise colorfastness. However, with pre-colored POY, pigments are locked into the polymer structure, resisting fading even when exposed to harsh chemicals or UV radiation. Similarly, in outdoor applications such as awnings or marine upholstery, the yarn’s resistance to hydrolysis and microbial growth ensures longevity without sacrificing color depth.

Yet challenges remain. For example, achieving bright, neon shades in industrial-grade POY often requires higher pigment loads, which can slightly reduce tensile strength. Manufacturers address this by blending masterbatches with advanced dispersants, ensuring vibrant hues without compromising mechanical properties. This innovation has opened doors for niche markets like safety gear, where visibility and durability are equally critical.

Sustainability Meets Innovation

The shift toward sustainable practices has further elevated the role of polyester colored POY. By eliminating post-production dyeing, it reduces water consumption by up to 50% and cuts chemical waste—a key advantage for eco-conscious brands. Recycling is another frontier: while colored POY poses challenges for repurposing due to mixed pigments, advancements in chemical recycling now allow manufacturers to recover pure polymer chains, paving the way for closed-loop systems.

Conclusion: A Future-Proof Solution

Polyester colored POY is no longer just a raw material—it’s a strategic asset for industries demanding reliability, efficiency, and sustainability. Whether it’s streamlining high-speed production lines or enabling bold designs in technical textiles, its adaptability continues to redefine boundaries. As textile technology evolves, expect this unsung hero to play an even greater role in shaping smarter, more resilient fabrics for tomorrow’s world.

English

English 中文简体

中文简体

Home

Home