When it comes to working with FDY (polyester full stretch yarn) on round knitting or warp knitting machines, one of the most common queries we get is about the recommended processing speeds. While the speed at which you run your machines can depend on various factors, such as machine type, yarn specifications, and fabric quality requirements, it’s crucial to strike a balance between efficiency and maintaining the quality of the end product.

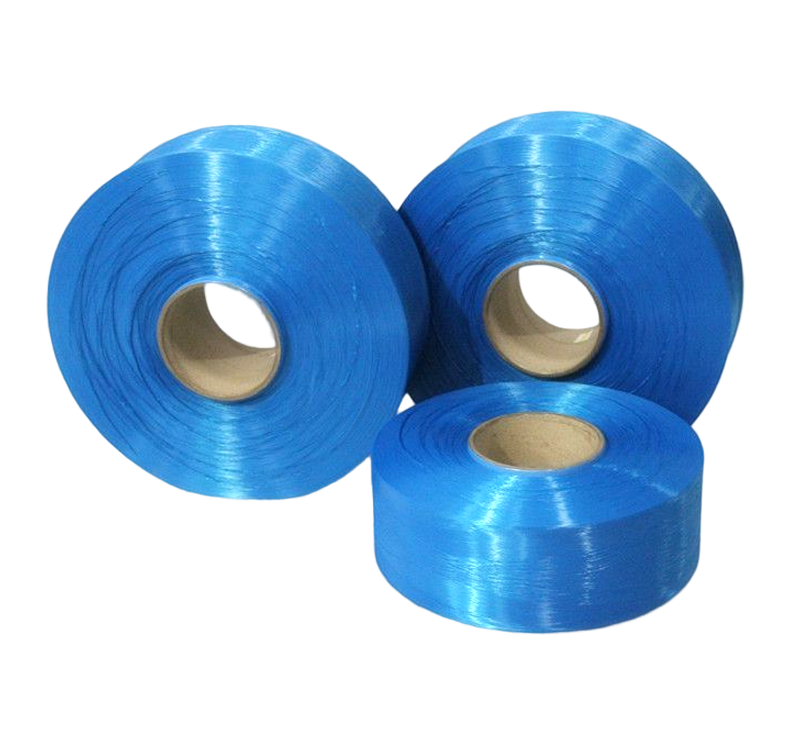

Firstly, it’s important to recognize that FDY yarn, produced using native spinning technology, is designed to deliver superior performance. This includes a high degree of stretch and excellent color fastness, making it a versatile choice for applications like home textiles, luggage, and webbing. However, to fully exploit these qualities, you need to adjust the processing speed to suit the yarn’s characteristics. Running the machine too fast could compromise the stretchability and the yarn’s overall appearance, potentially causing irregularities like uneven tension or fabric distortions. On the other hand, running it too slow may lead to under-utilization of machine capacity, increasing production time and costs.

For round knitting machines, which typically operate in a circular fashion, the ideal speed generally ranges from 100 to 200 rpm (revolutions per minute), depending on factors like the yarn's denier, twist level, and the fabric’s stretch requirements. If you're working with a finer denier FDY yarn, you may need to adjust to a lower speed, as the finer fibers tend to be more delicate and can easily break or deform at higher speeds. On the other hand, for heavier yarns, slightly higher speeds can be used without risking damage.

When dealing with warp knitting machines, the speed can vary significantly based on the type of pattern and fabric you’re aiming to create. Typically, warp knitting machines can run at speeds between 300 to 500 rpm. For FDY yarns, especially if they’re being used in more complex knitted structures, you might want to start at a moderate speed and gradually increase it while monitoring fabric quality closely. The stretch properties of FDY yarn can help achieve smooth, consistent fabric surfaces, but high processing speeds can also lead to issues like yarn slipping or losing elasticity over time. Therefore, careful speed regulation is essential to avoid excessive wear or deformation of the yarn during production.

In both cases, it’s also essential to consider the overall production environment. Factors like humidity, tension, and temperature can affect the yarn's behavior during the knitting process, so adjusting the machine settings accordingly will help maintain consistency. Ensuring proper yarn tension is crucial, as FDY yarns are more prone to stretching than other synthetic yarns, which could impact the final fabric’s feel and durability if not carefully controlled.

Ultimately, the best way to determine the ideal processing speed is through experimentation and close monitoring of the machine performance in relation to the desired fabric outcome. Fine-tuning the speed to match both the yarn’s capabilities and your machine’s settings will help you achieve the best results. And as always, don’t forget to test for consistency in every batch—high-quality FDY yarn, when processed correctly, can lead to exceptional textiles that meet even the highest standards of durability and performance.

English

English 中文简体

中文简体

Home

Home