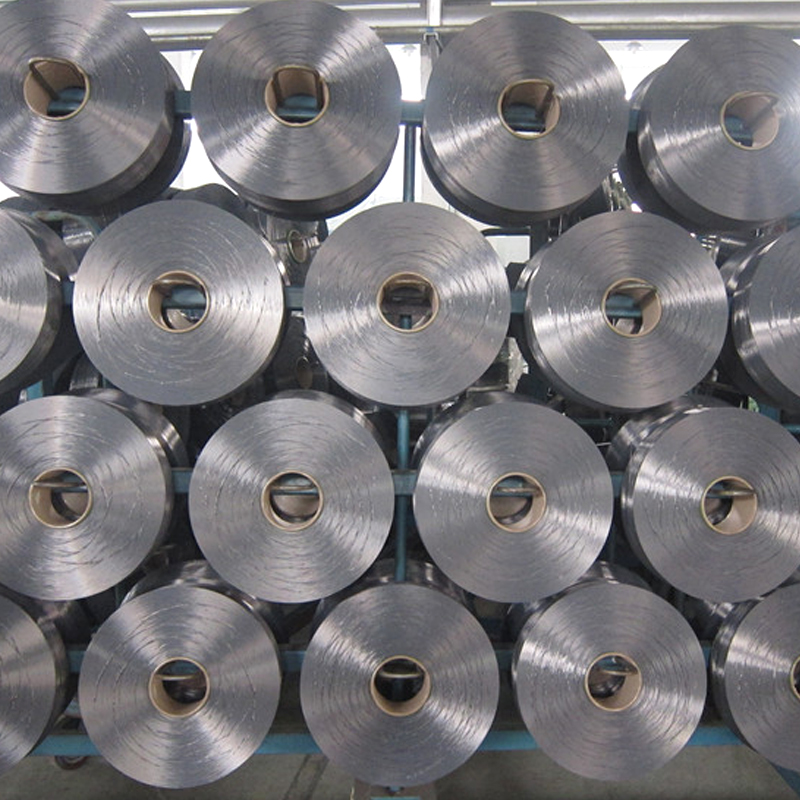

Partially Oriented Yarn (POY), the quality and color consistency are directly influenced by two key components in the process: polymer chips and color masterbatch. These elements are fundamental in shaping the final yarn's performance, appearance, and suitability for various textile applications. Understanding the intricate role of these ingredients provides valuable insights into the factors that affect POY's end use in everything from high-performance fabrics to everyday textiles.

Polymer chips, typically made from polyester or other synthetic materials, are the foundational building blocks in POY production. The choice of polymer chips impacts everything from the fiber's strength and elasticity to its overall processing behavior. The purity of the polymer chips, as well as the molecular weight and distribution, plays a critical role in determining the yarn’s tenacity and elongation. Higher-quality polymer chips often result in POY with better mechanical properties, ensuring a stronger and more durable final product. In addition, the uniformity of the chips is key to consistent fiber formation during the melt spinning process, which translates into a smooth and high-quality yarn that is free from defects such as breakage or uneven thickness.

Color masterbatch, which is essentially a concentrated blend of pigments or dyes, is another crucial factor that affects the consistency and vibrancy of the color in POY. The choice of masterbatch is especially important when producing colored POY, as it directly determines the yarn’s hue, brightness, and color fastness. A high-quality color masterbatch ensures that the desired color is uniformly dispersed throughout the polymer during the spinning process, eliminating issues like streaks or color variations. The consistency of color in POY is largely determined by the dispersion quality of the masterbatch. Poor dispersion can result in uneven color throughout the yarn, making it difficult to achieve the desired look in the final product. Furthermore, the stability of the color masterbatch is crucial for ensuring long-lasting color performance. High-quality masterbatches are engineered to withstand the heat and mechanical stress of subsequent processing steps, such as texturing or dyeing, without fading or losing their intensity.

The synergy between polymer chips and color masterbatch is what ultimately determines the quality and color consistency of POY. A mismatch in either of these elements can lead to significant issues, such as poor yarn quality, uneven dye uptake, or compromised color fastness. For example, using low-quality polymer chips with inconsistent molecular weights can result in a yarn that lacks uniformity, which can then cause uneven coloration when combined with an inferior masterbatch. In contrast, selecting the right polymer chips and color masterbatch that complement each other ensures that the POY not only performs well in terms of strength and durability but also exhibits consistent, vibrant colors throughout its entire length.

Moreover, advancements in polymer chip and masterbatch technology have made it possible to enhance both the mechanical properties and aesthetic qualities of POY. For instance, innovations in color masterbatch formulations have enabled the production of Partially Oriented Yarn with colors that resist fading under exposure to light, heat, or washing. This makes it increasingly easier for manufacturers to create products that maintain their visual appeal and performance over time. Additionally, sustainable practices are emerging, such as the use of recycled polymer chips and eco-friendly colorants, which contribute to reducing the environmental impact of POY production while maintaining high standards of quality and consistency.

The choice of polymer chips and color masterbatch is crucial in determining the overall quality and color consistency of Partially Oriented Yarn. These elements not only influence the physical properties of the yarn but also play a key role in ensuring that the color remains vibrant and uniform throughout its use. By selecting high-quality polymer chips and masterbatches, manufacturers can ensure a superior POY product that meets the demands of the textile industry, offering both aesthetic appeal and robust performance across a range of applications.

English

English 中文简体

中文简体

Home

Home