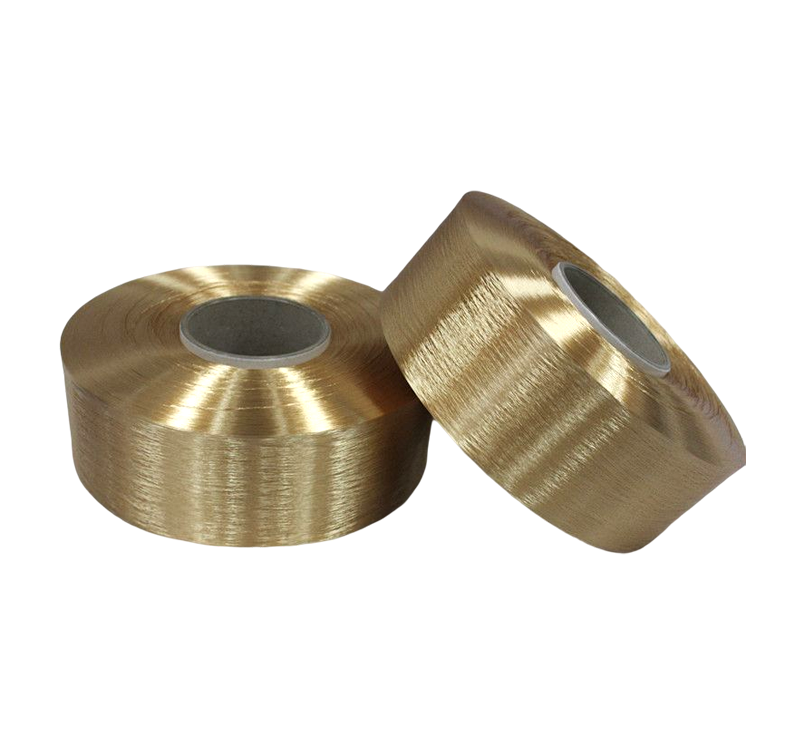

Polyester full stretch yarn (FDY) is a versatile and high-performance material widely used in the textile industry, especially in home textiles such as round knitting, warp knitting, webbing, and luggage fabrics. Its enhanced performance is largely due to advancements in materials science and processing technologies. Among these, the use of color masterbatch in its production plays a pivotal role. The incorporation of color masterbatch not only influences the aesthetics of the yarn but also significantly enhances its overall functionality, adding value for both manufacturers and end-users.

Color masterbatch is a concentrated mixture of pigments or additives encapsulated into a carrier resin, which is then mixed with raw polymer materials during the extrusion process. In the production of polyester FDY, the color masterbatch is blended with bright polyester chips using native spinning technology, ensuring that the yarn not only achieves vibrant and consistent coloration but also retains high performance. This integrated color solution provides several advantages over traditional dyeing methods, making the process more efficient and sustainable.

One of the key benefits of using color masterbatch in polyester FDY production is the exceptional color fastness it imparts to the yarn. Color fastness, the resistance of a material’s color to fading or running, is crucial for products that undergo repeated washing, exposure to sunlight, and friction in daily use. The masterbatch ensures that the pigments are evenly dispersed throughout the yarn during the spinning process, resulting in a stable and durable color that maintains its vibrancy over time. This is particularly important in applications like home textiles and luggage, where durability and aesthetic longevity are major selling points.

Another important aspect of color masterbatch is its contribution to production efficiency. By introducing color at the raw material stage rather than post-production dyeing, manufacturers can eliminate the need for separate dyeing processes, reducing water consumption, energy use, and overall production time. This streamlined process not only cuts costs but also minimizes the environmental impact of the production process. With sustainability becoming an increasingly important factor in the textile industry, the use of color masterbatch in polyester FDY offers a competitive edge to manufacturers looking to reduce their carbon footprint without compromising on quality.

The integration of color masterbatch also opens up broader possibilities for customization. Polyester full stretch yarn can be tailored to meet specific customer needs in terms of color, texture, and performance, all while maintaining the superior mechanical properties of the yarn. This level of customization is highly desirable in sectors such as fashion, home décor, and technical textiles, where brand differentiation and unique product offerings are essential. Color masterbatch technology allows manufacturers to cater to these demands without incurring the logistical challenges and costs associated with small-batch dyeing.

Furthermore, the use of color masterbatch aligns with the broader trend of innovation in textile materials. Polyester FDY is known for its tensile strength, elasticity, and smooth finish, making it ideal for a wide range of applications. By incorporating color masterbatch, manufacturers enhance these qualities with vibrant, lasting colors, offering products that are both functional and aesthetically pleasing. This combination of form and function is what makes polyester FDY a popular choice across various sectors, from home textiles to industrial applications.

The role of color masterbatch in enhancing Polyester full stretch yarn goes beyond simple coloration. It is a key factor in ensuring superior color fastness, optimizing production efficiency, enabling customization, and supporting sustainable manufacturing practices. As the textile industry continues to evolve, innovations like the use of color masterbatch in polyester FDY production will remain integral to delivering high-quality, versatile, and environmentally conscious products to the market.

English

English 中文简体

中文简体

Home

Home