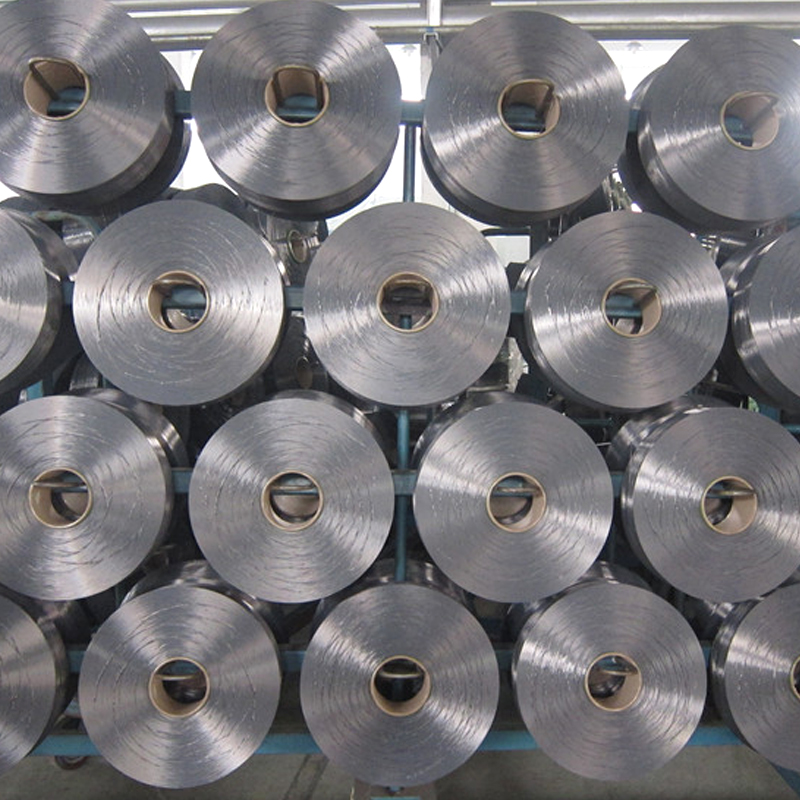

Polyester Partially Oriented Yarn (POY) is a specialized type of polyester yarn that plays a pivotal role in the textile industry. It is produced through a high-temperature melt spinning process, utilizing polymer chips and color masterbatch to achieve its distinctive characteristics. The yarn is named "partially oriented" because it undergoes partial stretching during production, which influences its subsequent processing and end-use properties. Understanding how POY differs from Fully Oriented Yarn (FOY) and Draw Textured Yarn (DTY) requires a look into their production processes, structural properties, and applications.

POY differs significantly from FOY and DTY in terms of its orientation and intended use. FOY, or Fully Oriented Yarn, is subjected to a more extensive stretching process during its production. This thorough stretching imparts a high degree of orientation to the polymer chains, resulting in a yarn that is stronger and more stable than POY. FOY is designed for applications where high tensile strength and dimensional stability are crucial, such as in the production of industrial fabrics and high-performance textiles. Its complete orientation means it has already undergone substantial stretching, making it less flexible compared to POY and not as suitable for further processing into textured yarns.

On the other hand, DTY, or Draw Textured Yarn, is produced by further processing POY through a texturizing process. This involves additional stretching and texturizing steps that create a crimped or textured structure, which enhances the yarn's bulk and elasticity. DTY is prized in the textile industry for its soft touch, stretchability, and ability to mimic the appearance and feel of natural fibers like cotton. While POY serves as a versatile precursor in the production of DTY, the texturizing process endows DTY with distinct characteristics that are ideal for applications requiring a more tactile and aesthetically appealing yarn.

The key distinction between these yarn types lies in their orientation and processing stages. POY is less oriented and is typically used as a starting material for further processing. It provides the flexibility needed for subsequent yarn manipulation and texturizing. FOY, with its complete orientation, is utilized in applications demanding high strength and stability, often directly in end products. DTY, with its texturized structure, caters to applications needing enhanced softness and stretch. The varying degrees of orientation and processing result in yarns that cater to different needs within the textile industry, from high-performance applications to consumer products with specific tactile and aesthetic qualities.

The main differences between POY, FOY, and DTY revolve around their production processes and resulting properties. POY serves as a foundational yarn with partial orientation, suitable for further processing into textured or high-performance variants. FOY is highly oriented, offering superior strength and stability for specific applications. DTY, created from POY through additional texturizing processes, provides enhanced softness and elasticity. Each type of yarn has its unique place in the textile industry, driven by its distinct characteristics and intended applications.

English

English 中文简体

中文简体

Home

Home