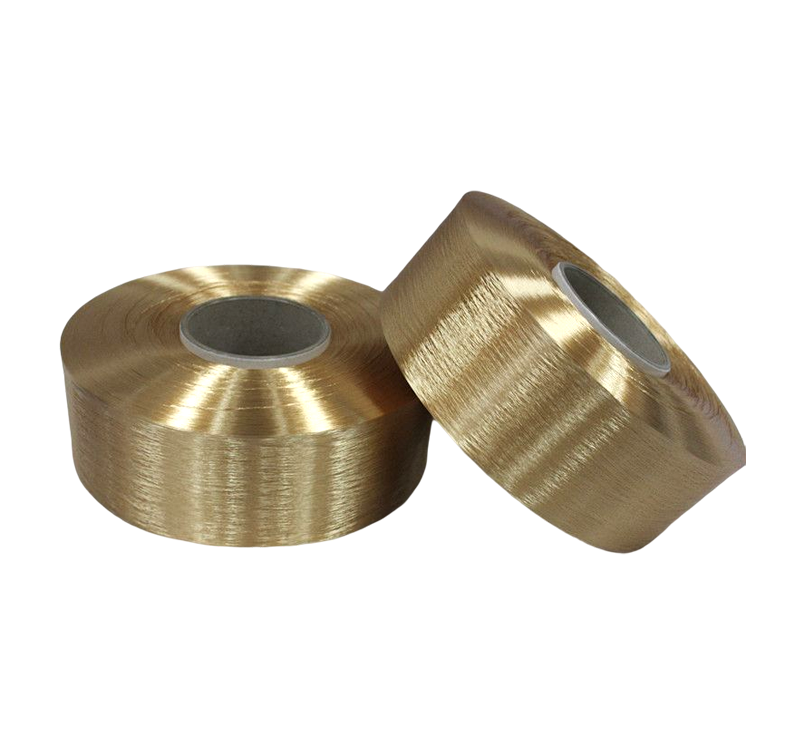

Polyester full stretch yarn, often recognized for its excellent performance and versatility, is produced using bright polyester chips and color masterbatch through native spinning technology. This innovative method not only enhances the quality of the yarn but also ensures stable and reliable color fastness, making it suitable for a wide array of applications in home textiles, including round knitting, warp knitting, webbing, and luggage production. Understanding the recommended processing methods for this type of yarn is crucial for manufacturers aiming to optimize the quality and durability of their end products.

The processing of polyester full stretch yarn begins with careful preparation. The yarn must be stored in a controlled environment to prevent moisture absorption, which can affect its properties during subsequent processing stages. Proper storage also helps maintain the yarn's brightness and color integrity. When preparing for knitting or weaving, it is essential to ensure that the yarn is free from tangles and inconsistencies. Using high-quality feeding systems during the knitting or weaving processes can minimize the risk of breakage and enhance the overall production efficiency.

During the actual knitting or weaving process, attention to machine settings is vital. Adjustments may be required to accommodate the specific denier and stretch characteristics of the polyester full stretch yarn. For example, tighter tension settings might be necessary to achieve the desired elasticity without compromising the fabric's integrity. It's also beneficial to conduct test runs to determine the optimal settings for different applications, ensuring that the fabric produced meets quality standards while maximizing the yarn's inherent stretch capabilities.

Post-processing treatments play a significant role in enhancing the performance of Polyester full stretch yarn. Techniques such as heat setting can be employed to stabilize the yarn and fabric dimensions, thereby reducing shrinkage and improving overall durability. Additionally, chemical treatments may be applied to impart specific functionalities, such as moisture-wicking properties or UV resistance, which can further enhance the yarn's appeal in the market. It’s important for manufacturers to be aware of these options and choose treatments that align with the intended use of the final product.

Finally, quality control measures throughout the processing stages are essential to ensure that the finished fabrics meet industry standards. Regular inspections for color fastness, tensile strength, and elasticity should be conducted. By integrating comprehensive quality assessments, manufacturers can identify and rectify issues early in the production process, thereby minimizing waste and ensuring customer satisfaction.

The processing methods for polyester full stretch yarn in textile production encompass a range of practices that require careful attention to detail, from storage and preparation to machine settings and post-processing treatments. By understanding and implementing these methods effectively, manufacturers can leverage the advantages of polyester full stretch yarn to produce high-quality textiles that meet the diverse needs of consumers in today’s market.

English

English 中文简体

中文简体

Home

Home