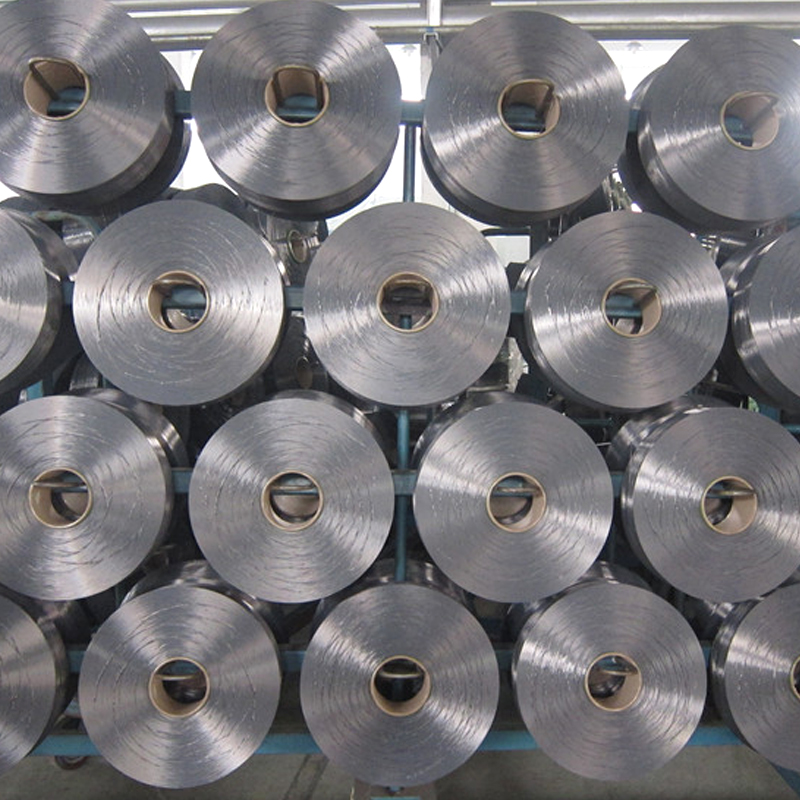

The production of color POY (Partially Oriented Yarn) has been profoundly shaped by several technological advancements that have revolutionized its manufacturing process and application. At the heart of these advancements is high-temperature melt spinning technology. This innovation allows for the precise control of the polymer melt at elevated temperatures, ensuring that color masterbatches are evenly distributed throughout the yarn. This precision is critical for achieving the vibrant and consistent colors that define color POY yarn, making it a versatile and reliable material in various textile applications.

Color masterbatch technology has also played a pivotal role. The development of advanced color masterbatches has enabled manufacturers to achieve superior color consistency and fastness. Masterbatches are concentrated pigment preparations that are mixed with polymer during the spinning process, allowing for accurate color control and integration. This technological leap ensures that the color POY yarn maintains its hue and vibrancy over time, even under demanding conditions.

Improvements in polymer science have further enhanced the quality of color POY yarn. Modern polyester polymers are engineered to have better dye uptake and increased resistance to fading and degradation. These advancements result in yarns with superior performance characteristics, including enhanced color retention and durability. Coupled with this, the advancement of filtration and cleaning technologies has ensured that the polymer melt used in spinning is free from impurities, leading to a more consistent and high-quality yarn.

Automation and control systems have revolutionized the manufacturing process by introducing precise monitoring and control capabilities. These systems allow for real-time adjustments and ensure that the spinning process remains consistent, producing yarn with uniform properties and color. The evolution of dyeing and finishing technologies has also contributed to the efficiency of color POY yarn production. Modern dyeing methods enhance color fastness while minimizing environmental impact, aligning with sustainability goals.

Environmental and sustainable practices have become increasingly important, with innovations in green chemistry leading to more eco-friendly production processes. These practices include the use of environmentally friendly dyes and the implementation of waste reduction techniques. Additionally, the integration of nanotechnology has introduced new possibilities, such as yarns with enhanced properties like increased durability and improved resistance to environmental factors.

Recycling technologies have also advanced, allowing for the reuse of polyester materials, including color POY yarn. This development supports more sustainable production practices and reduces the overall environmental footprint of the yarn.

Color POY yarn benefits from these technological advancements in several ways. It offers superior color consistency and fastness, making it a preferred choice in applications where vibrant and lasting colors are essential. Its enhanced durability and performance characteristics ensure that products made from color POY yarn maintain their quality and appearance over time. As technology continues to evolve, the production of color POY yarn is likely to see further improvements, contributing to its continued success in the textile industry.

English

English 中文简体

中文简体

Home

Home